Products

Contact Us

No. 20, Xinxing Road, Liujia Industrial Zone, Hengli Town, Dongguan, Guangdong Province

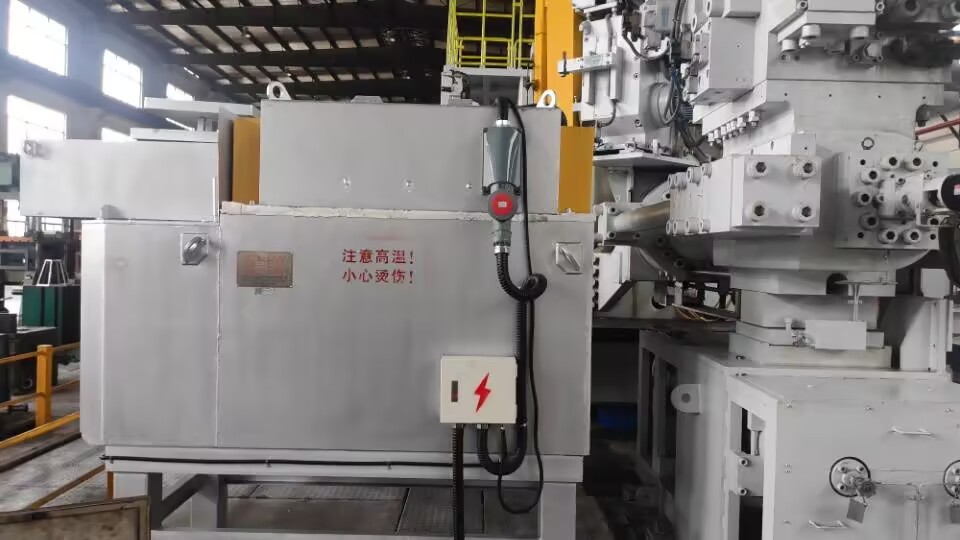

SPM pool type electric holding furnace

Classification:

keyword:

SPM pool type electric holding furnace

E-mail:

Message

DESCRIPTION

This furnace is designed as a specialized equipment for aluminum alloy machine edge electrical insulation, using imported non stick aluminum castables poured into a pool structure without the need for crucibles. It has the advantages of long service life,strong heating capacity,low surface temperature, low energy consumption,and easy operation.

The design of this furnace is centered around the user and oriented towards practical operation and use. The internal structure is made of imported castables as the inner lining, anti-seepage layer, imported nano microporous plate,and ceramic fiber board as insulation materials. The design pursues meeting the high aluminum soup requirements of customers with the lowest holding temperature as the standard, ensuring the service life of the furnace, effectively reducing surface heat loss, and reducing aluminum surface oxidation. It is a high-performance aluminum alloy special electric insulation furnace that pursues energy conservation to the extreme and has interational advanced level.

Structure of the furnace

Main body shell components

·The outer body and bottom plate are welded with 8mm A3 steel plates,and the chassis is welded with national standard channel steel.Except for the internal insulation layer and working layer, it is basically constructed with metal welding.

·The four support legs of the baseare made of adjustable threaded columns,which can be adjusted with nuts to achieve the desired height (can be made according to customer needs).

Furnace lining structure

The lining inside the furnace consists of an outer shell iron plate, a heat shield coating, a calcium silicate board, a ceramic fiber board+nano microporous board, an anti aluminum liquid waterproof penetration layer, and a pouring layer,arranged in order from the outside to the inside.The pouring layer adopts imported non stick aluminum castable, and the insulation is arranged in a certain order through thermal conductivity calculation, so that the surface temperature of the insulation furnace is kept below room temperature+30℃,improving the high- temperature working environment of the workshop,further reducing energy consumption,and enhancing the competitiveness of the product. Under normal usage conditions, the service life is over 3 years.

Parameters

|

Model |

The retention amount of aluminum liquid |

Equipped with powver/reference energy consumption data |

Reference die-casting machine |

|

SPM-500KG |

500KG |

21KW/9° |

280T-350T |

|

SPM-650KG |

650KG |

24KW/11° |

350T-500T |

|

SPM-850KG |

850KG |

27KW/13° |

500T-800T |

|

SPM-1000KG |

1000KG |

36KW/15° |

650T-800T |

|

SPM-1200KG |

1200KG |

36KW/18° |

800T-1000T |

|

SPM-1500KG |

1500KG |

45KW/20° |

1000T-1250T |

|

SPM-2000KG |

2000KG |

60KW/26° |

1250T-1650T |

|

SPM-2500KG |

2500KG |

75KW/32° |

2000T |

|

SPM-3000KG |

3000KG |

90KW/38° |

2500T |

Pre

Siguiente

GLOBAL COOPERATION

GD MIDEA SMALL DOMESTIC APPLIANCE MFG.CO.,LTD

Guangdong Vanward New Electric Co., Ltd.

Yizumi Holdings Co., Ltd.

Huizhou NVC Lighting Technology Co., Ltd.

RELATED PRODUCTS

Our Advantages

Integrity, Innovation, and Struggle

With ample experience

More than 30 years of experience in the industry, specialising in the combination of pressure casting furnace technology with energy saving and environmental protection

Quality control

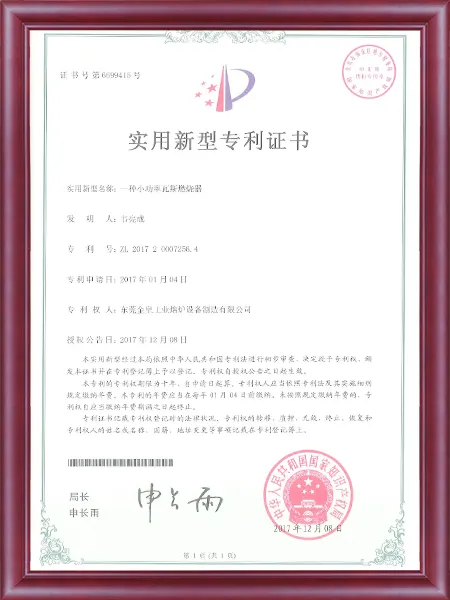

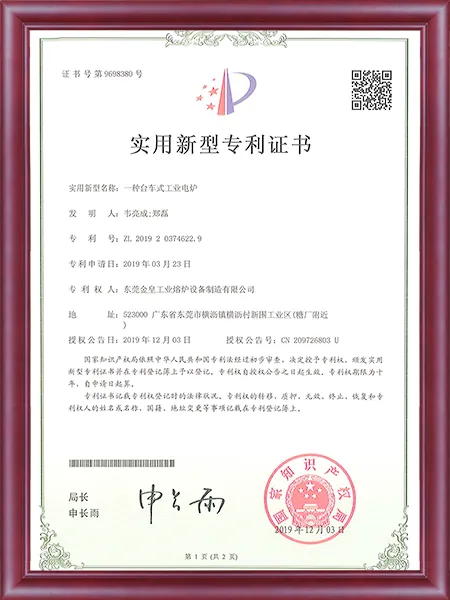

The company has passed ISO9001:2015, ISO14001:2015 and ISO45001:2018 international quality management system certification, Some furnace forms have obtained CE certification.

Quality services

The company has a professional after-sales service team with 7 x 24 hours customer service and quick response!

Customer Case

Create more value for customers and ultimately achieve a win-win situation